Product Name : Gearheads and motor installation manual

Description

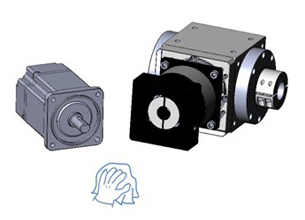

Step 1:

Double-check the motor and gearbox size. Clean the mounting surface.

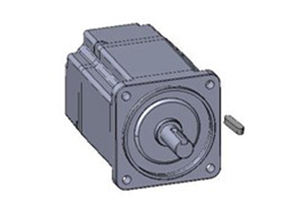

Step 2:

Remove the motor key.

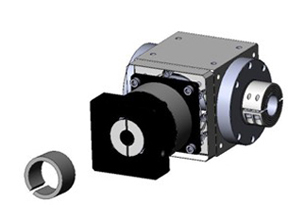

Step 3:

Check motor shaft size and insert bushing if necessary.

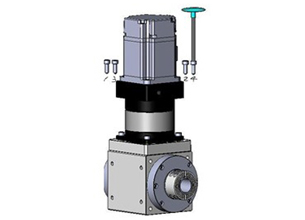

Step 4:

Set at vertical position.

Tighten the mounting bolts (including washer) in 1~4 order with wrench to 5% specified torque. (See table 1)

Step 5:

Tighten the input shaft bolt with torque wrench to specified torque.(See table2)

Step 6:

Tighten the mounting bolts in 1~4 order with torque wrench to specified torque. (See table1)

| Table 1 | Tightening Torque Recommended for Motor Mounting Bolt | ||||||

|---|---|---|---|---|---|---|---|

| Bolt Size | Width Across Flats | Strength 8.8 Tightening Torque | Strength 10.9 Tightening Torque | Strength 12.9 Tightening Torque | |||

| [mm] | [Nm] | [In-lbs] | [Nm] | [In-lbs] | [Nm] | [In-lbs] | |

| M3 x 0.5P | 2.5 | 1.3 | 12 | 1.8 | 16 | 2.1 | 19 |

| M4 x 0.7P | 3 | 3 | 27 | 4.1 | 37 | 4.9 | 44 |

| M5 x 0.8P | 4 | 6.1 | 55 | 8.2 | 73 | 9.8 | 87 |

| M6 x 1P | 5 | 11 | 98 | 14 | 124 | 17 | 151 |

| M8 x 1.25P | 6 | 25 | 222 | 34 | 302 | 41 | 364 |

| M10 x 1.5P | 8 | 49 | 434 | 67 | 594 | 80 | 709 |

| M12 x 1.75P | 10 | 85 | 753 | 116 | 1028 | 139 | 1232 |

| M14 x 2P | 12 | 137 | 1214 | 186 | 1648 | 223 | 1976 |

| M16 x 2P | 14 | 210 | 1860 | 286 | 2534 | 343 | 3038 |

| Table 2 | Tightening Torque Recommended for Set Collar Torque | |||||

|---|---|---|---|---|---|---|

| Gearbox Size | Motor Shaft Dia | Bolt Size | Width Across Flats | Tightening Torque | ||

| [mm] | [mm] | [mm] | [Nm] | [In-lbs] | ||

| RXW085A | Single | ≤14 | M4 x 0.7P | 3 | 4.1 | 37 |

| Double | ≤14 | M4 x 0.7P | 3 | 9.5 | 85 | |

| RXW105A RXW125B |

Single | ≤24 | M6 x 1P | 5 | 14 | 124 |

| Double | ≤24 | M6 x 1P | 5 | 14 | 124 | |

| RXW125A RXW150B |

Single | ≤28 | M8 x 1.25P | 6 | 34 | 302 |

| Double | ≤28 | M8 x 1.25P | 6 | 34 | 302 | |

| RXW150A RXW180B |

Single | ≤38 (≤50) | M10 x 1.5P | 8 | 67 | 594 |

| Double | ≤38 (≤50) | M10 x 1.5P | 8 | 67 | 594 | |

| RXW180A RXW220A |

Single | ≤42 (≤50) | M12 x 1.75P | 10 | 116 | 1028 |

| Double | ≤42 (≤50) | M12 x 1.75P | 10 | 116 | 1028 | |